How to judge the delivery capacity of Jacquard Home Textile Fabrics Suppliers from production capacity?

1. Production scale and facilities

Production scale is one of the most intuitive indicators for evaluating the delivery capacity of suppliers. The scale of production facilities directly affects whether it can cope with large-volume orders and short-term order demand.

Factory scale: First, evaluate the factory area and number of production lines of the supplier. Large-scale production facilities can usually accommodate more production lines, which means that multiple orders can be produced at the same time, thereby speeding up the overall production progress. If the supplier's factory is relatively small and the number of production lines is limited, it may face production capacity bottlenecks when handling large orders, resulting in delivery delays.

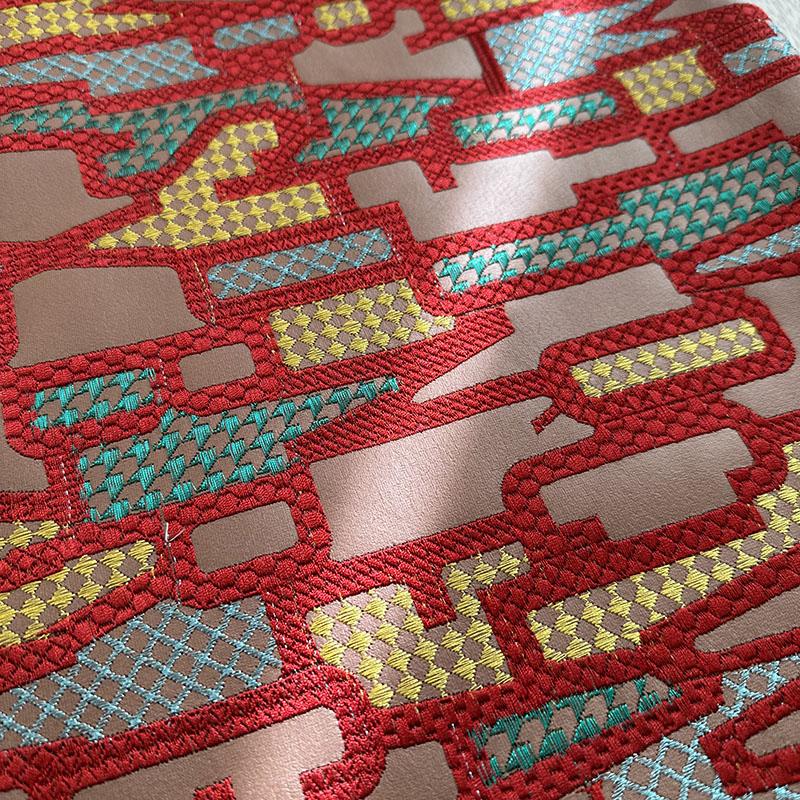

Equipment: Jacquard Home Textile Fabrics' production requires highly sophisticated equipment, including electronic looms, automated textile equipment, etc. It is very important to understand the supplier's equipment updates and modernization. Efficient and advanced equipment can improve production efficiency, shorten production cycles, and improve the stability of order delivery. On the contrary, old or manual equipment will increase production uncertainty, thereby extending delivery time.

Automation and digitalization level: Modern Jacquard Home Textile Fabrics Suppliers may use automated production lines and intelligent management systems, which can significantly improve production efficiency and reduce human errors. For example, advanced scheduling systems and real-time monitoring technologies can ensure the efficient operation of the production line, detect problems in time and take corrective measures to ensure on-time delivery.

2. Production cycle and delivery commitment

The production cycle refers to the length of time from receiving an order to completing production. Different types of Jacquard home textiles have different production cycles due to differences in process, raw materials, etc. Assessing whether the supplier's production cycle is reasonable is the key to judging its delivery capacity.

Reasonableness of production cycle: Whether the supplier can provide a detailed production plan and a clear delivery schedule indicates the maturity of its production management. If the supplier can provide personalized delivery cycles according to different order requirements and can deliver on time in most cases, it means that its production capacity is strong and its delivery capacity is more reliable. On the contrary, if the supplier's production cycle is always delayed or cannot provide a clear delivery date, it means that there may be problems with its production capacity.

Ability to cope with production peaks: Many Jacquard home textile suppliers experience order peaks in certain seasons. For example, market demand may increase significantly before holidays. Assessing whether the supplier can maintain a normal production rhythm during peak production and whether it can complete orders on time, especially large orders, is an important criterion for judging its delivery capacity. Whether the supplier has emergency production plans, such as overtime production, deployment of production lines or temporary increase of labor, can also reflect its ability to cope with peak periods.

3. Human Resources and Technical Strength

Production capacity is not only directly related to facilities and equipment, but also closely related to human resources and technical strength. Having an experienced technical team and skilled production workers is an important factor in ensuring timely and high-quality delivery.

Experience and ability of the technical team: The production of Jacquard fabrics involves complex weaving technology and design processes. The ability of the technical team directly affects the production progress and product quality. If the supplier's technical team has rich experience and can effectively solve various problems arising in the production process, then the production progress and delivery time will be more guaranteed.

Proficiency and training mechanism of production workers: The proficiency of workers is also a key factor affecting production efficiency. Whether the supplier conducts technical training regularly to improve workers' operating skills and work efficiency can increase production speed and reduce losses and rework caused by improper operation, and ensure timely delivery.

4. Production planning and scheduling management

Production planning and scheduling management are crucial to delivery capabilities. Effective production scheduling can ensure smooth connection between various production links and avoid production delays caused by scheduling conflicts or improper resource allocation.

Rationality of production scheduling: Evaluate whether the supplier adopts a modern production scheduling system to ensure that various links of production (such as weaving, dyeing, finishing, etc.) can be efficiently connected. A reasonable schedule can minimize idle time, improve equipment utilization and production efficiency, thereby shortening the production cycle and ensuring delivery time.

Flexible adjustment ability: When special circumstances occur, such as raw material shortages, equipment failures or sudden orders, whether the supplier can quickly adjust the production plan, optimize resources and reschedule production is an important aspect of judging its production capacity and delivery capacity. Suppliers with good production scheduling capabilities can make quick adjustments when encountering sudden problems to ensure on-time delivery.

5. Quality control and production stability

Production capacity is not only reflected in quantity, but also in quality stability. Jacquard fabrics have high requirements for quality control due to their complex design and weaving process. If quality problems frequently occur during the production process, it will often affect the production progress and even delay delivery.

Quality control system: Does the supplier have a complete quality control system? Can it strictly monitor each link in the production process to ensure product quality? Quality problems will lead to rework or re-production, which will greatly affect delivery time. If the supplier can provide stable quality, it means that every link in its production process has been fully optimized to ensure on-time delivery.

Testing and quality assurance: Does the supplier have independent quality testing equipment and testing personnel to ensure that each batch of products is strictly inspected before leaving the factory to avoid quality problems affecting delivery.

6. Supply chain management capabilities

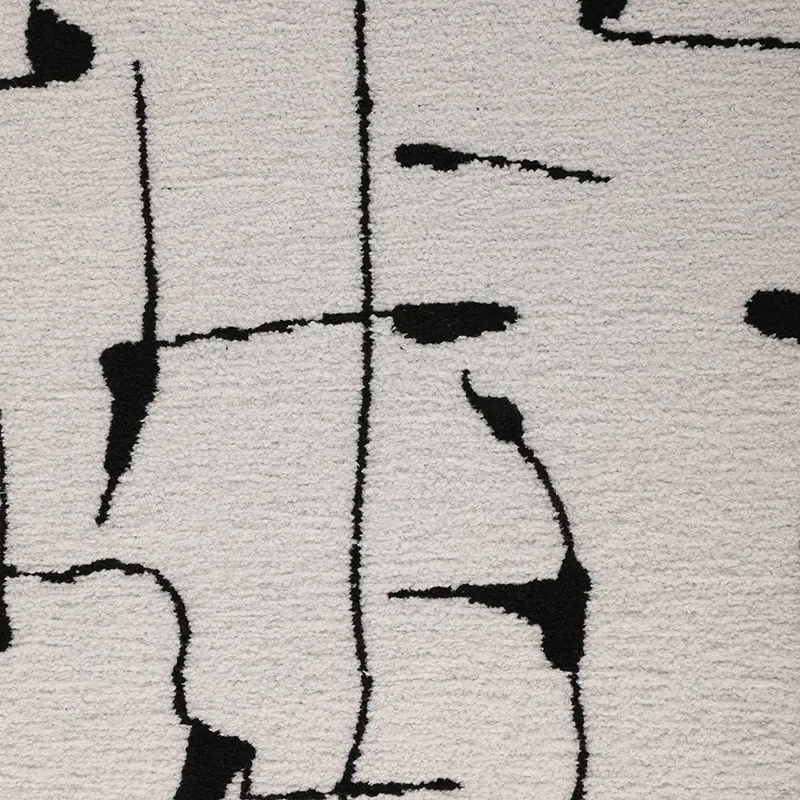

The production of Jacquard home textiles involves a variety of raw materials, such as high-quality yarns and dyes. The stability of the supply chain is a key factor in ensuring on-time delivery.

Stability of raw material supply: Does the supplier have a stable cooperative relationship with multiple raw material suppliers? Can it quickly respond to uncertainties in the supply of raw materials, such as price increases and transportation delays? If the supplier can guarantee a stable supply of raw materials, production delays caused by material shortages can be avoided during the production process.

Logistics capability: Does the supplier have an efficient logistics system to ensure that the finished products are transported to the customer's area in a timely manner? Timely logistics arrangements are also an important part of judging delivery capabilities.