Chenille’s innovative performance in digital design and production

Innovation in virtual layout and manufacturing has brought modern modifications to the Chenille cloth industry, improving product great, manufacturing efficiency, and marketplace competitiveness.

Application of CAD/CAM Technology: The utility of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technology is critical for digital layout and production. Manufacturers can utilize CAD software to layout diverse complicated cloth textures, patterns, and hues, knowing designers' creative ideas. CAM era then converts these designs into the specified production methods and parameters, drastically enhancing layout accuracy and production performance.

Personalized Customization Services: Digital design and manufacturing generation provide Chenille cloth producers with the possibility of imparting personalised customization offerings. Consumers can pick material textures, colors, and styles in keeping with their possibilities thru online platforms or specialized customization provider stores, and even publish their personal design drafts. Manufacturers can make use of CAD/CAM era to achieve rapid customized manufacturing, assembly customers' personalised desires and improving logo competitiveness.

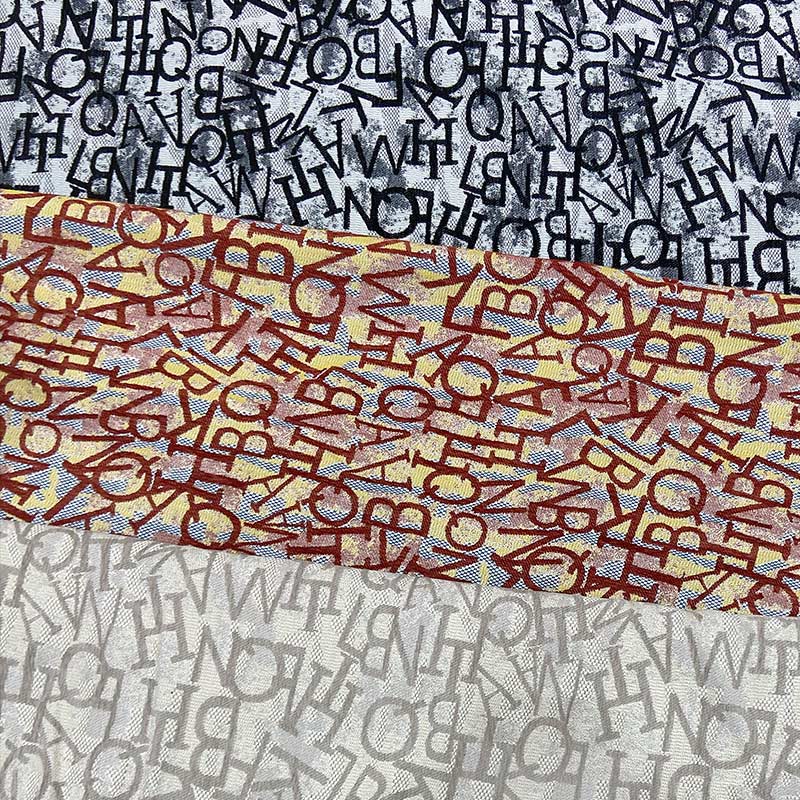

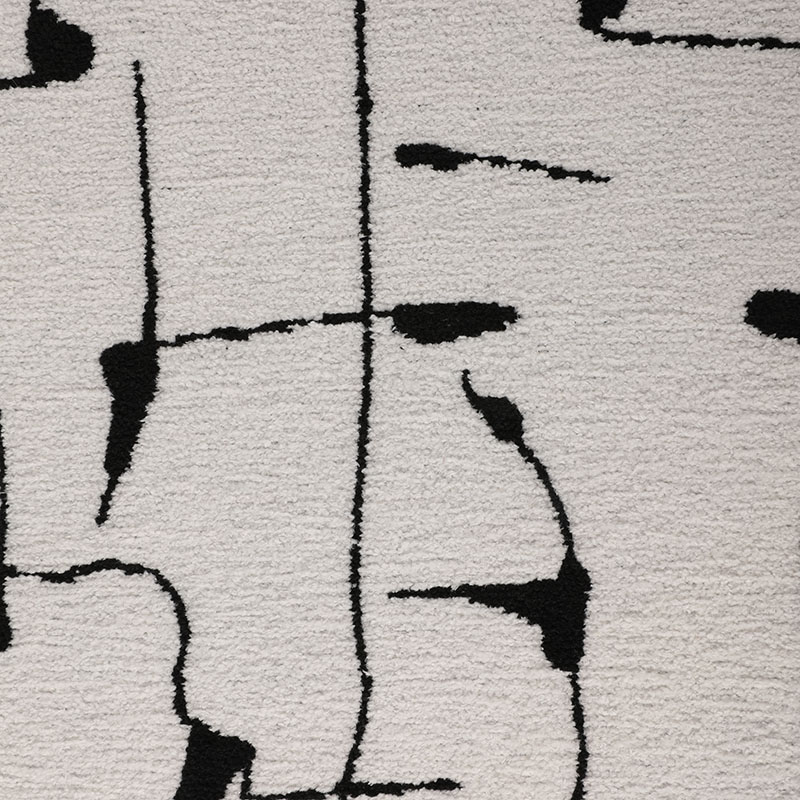

Innovation in Texture and Pattern Design: Digital design era has introduced extra innovative space for texture and pattern layout of Chenile fabric . Designers can create greater complex and delicate textures and styles thru CAD software, achieving specific control and modifications in element. Additionally, digital design promotes innovation in textures and patterns, constantly introducing novel and particular designs that entice extra consumer attention and favor.

Rapid Prototyping Technology: Digital layout and manufacturing technology offer powerful answers for speedy prototyping of Chenille material . Manufacturers can make use of 3-d printing technology or CNC reducing machines to fast produce sample fabric for fashion designer and purchaser evaluation and confirmation. This rapid prototyping generation shortens the product development cycle, reduces improvement charges, and improves the product's market responsiveness.

Intelligent Monitoring of Production Processes: Digital layout and production technology also can realise smart tracking and control of manufacturing techniques. Through sensors, IoT generation, and many others., the real-time tracking of production gadget operation repute and system parameters is feasible, improving production efficiency and product exceptional.

The utility of digital layout and manufacturing generation has introduced approximately amazing modifications and development opportunities for the Chenille fabric industry. Through the utility of CAD/CAM generation, customized customization offerings, innovation in texture and sample design, rapid prototyping technology, and sensible tracking of manufacturing procedures, Shniel cloth manufacturers constantly decorate product layout stages, production performance, and market competitiveness, meeting consumers' personalized wishes.